Discovers Fat Carbon Through the interview of Ovidijus Jucius, his creator.

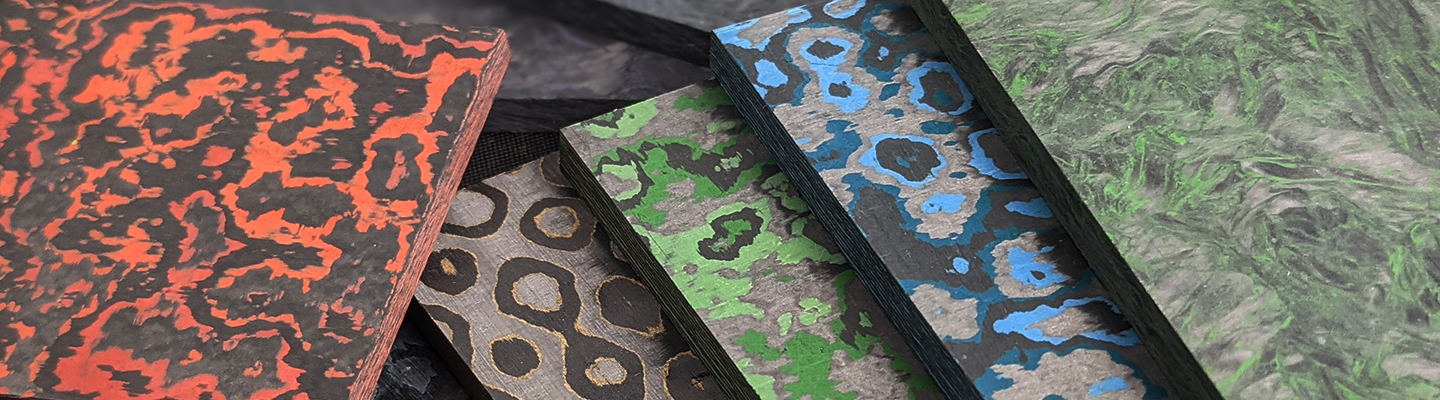

As you have seen, we have again in our range of pads! Indeed, we started a partnership with Fat Carbon, which carries out colorful carbon fiber platelets. Innovative and original, we are delighted to offer them to you.

To make you discover these products (if you do not know them yet), we preferred to give the floor to the Creator.

So you will find in this article of blog the presentation of Fat Carbon and its colorful carbon fiber pads as an interview made by our team.

Presentation of the company Fat Carbon

Who is Fat Carbon ? What brought you to this concept? Where can we meet you?

Ovidijus Jucius (OJ): Fat Carbon is a trusted provider that manufactures composite material based on carbon fiber. I started working with composites in 2009 in the mechanical sports sector. In these years, I saw that there was a need for sheets High thick carbon fiber for machining. I gradually developed techniques to make sheets up to 150mm thick. I sold some sheets To cutlers, they were looking for new things, so we tried to create something unique for them. That's how it all started.

Since when have you started using this process?

Oj: With Fat Carbon Materials, I started almost a year ago, in 2018, so we are still young.

Why have opted for these colors?

Oj: As far as colors are concerned, we listen to our friends and our customers who explain to us what they like and wish to have. Once we decided on the result we want to get, we manufacture the mussels and make several lots of tests until the result corresponds to our expectations.

Arctic Storm, Mars Valley ... These are whimsical names, how did you choose them?

Oj: For the choice of names of our products, again, our customers help us very much and we are very grateful. The last names like "Jungle Wear" and "Arctic Storm" were chosen from many guest suggestions via social networks.

Have you planned new colors or new patterns?

Oj: Yes, we will have new motifs that will come out this year;)

Colors are more appreciated than others depending on the country?

Oj: In fact, yes. For example, one of our most popular motives is the "Snakeskin", which contains either bronze or copper between each carbon fiber layer. In Europe, the most appreciated is the "Snakeskin Gold" with bronze, and the US: it's different, it's the copper version that is the most popular. It's the same for color fibers like "Arctic Storm", "Jungle Wear", "Mars Valley", some work better in the US and others in Europe.

Carbon fiber

What is carbon fiber?

Oj: A short response would be: a solid and light fiber, reinforced with plastic containing carbon fibers.

For the more scientific version: a composite material is made of two or more constituent materials having significantly different physical or chemical properties. Once combined, they make it possible to obtain a material that does not have the same characteristics as the two components used separately. In general, our materials are composed of carbon fiber and epoxy resin in a 60/40 ratio. In some cases, we add metal or ceramic pigments to obtain the desired effects.

Is it a matter that works easily? Is there a risk of breakage case?

Oj: All our products are rather simple to work. They do not require specific tools to start shaping them. You can use any tool such as a file, a kept, a back stand, a jigsaw etc ...

However, the cut generates abrasive dust, so we recommend using carbide tools to have a longer life of your tools. With regard to digital-controlled machining, the chosen tool usually depends on the need that we have. If you want to make only a few pieces then, even cheap HSS tools work very well. For more professional use, each tool manufacturer has a range of composite work.

With regard to surface finish, you can work with a hand abrasive with 380 grain. If you are looking for a glossy polished surface, you can mount until 1800 with polishing paste. Attention, you have to think of always carrying its protective elements (mask, gloves and glasses).

Does the coloring weaken carbon fiber?

Oj: Added color does not affect the composite strength significantly, however, add metal such as bronze or copper has some effects. The adhesion between the layers may be slightly less solid, which means that it is necessary to make a little more attention when working this carbon fiber, particularly during drilling or we recommend to reduce the speed. Advance.

Carbon fiber applications

What can be the applications of your carbon fiber pads?

Oj: The list of applications is endless, our customers use our products in many different areas such as cutlery, jewelery, watchmaking, interior decoration, automotive and many more ...

Can we have custom dimensions?

Oj: Yes The majority of patterns are available in size and tailored thicknesses, the manufacturing time is about 3 weeks.

A big thank you to Ovidijus Jucius from having lent himself to the game of the interview! You can find our selection of pads Fat Carbon In our materials for handles.