RWL34 ™ steel of Damasteel : Exceptional properties, and a story to its measure.

RWL34 ™, manufactured by Damasteel, is an exceptional cutlery steel to more than one title. It combines all the benefits that a cutter can search for the making of knife blades, whether fixed or folding: easy to work, it guarantees tenacity and resistance, while ensuring an excellent cutting edge. An ideal product, for parts that are aimed at excellence. The fruit of a long and beautiful story of enthusiasts, which we will present you in this blog article.

The East Meets the West: Aux Origins of RWL34™, the ats34

The story of this inxogible steel shade takes us to Japan. It is in the country of the rising sun that the first grind of RWL34 ™ steel is born. Forged and manufactured by Kobe Steel, it was used in the making of stainless steel cages, which surrounded ball bearings. Its exceptional resistance properties allowed the ball bearings, constantly subjected to friction of the latter, to maintain their efficiency longly in time. Nobody was scanning to use this steel in cutlery: it was not necessary for a visionary to appropriate, and transform this jewel from the Nippon know-how, into a steel that would offer to the cutlers all that one can expect from a nuance Stainless. This visionary? Robert W. Loveless.

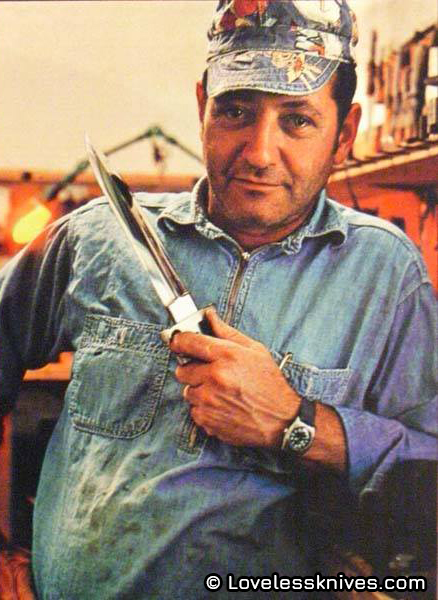

Bob W. Loveless, at the forefront of progress

But who is the one that the story affectionately nick "bob"? Born in 1929 and deceased and 2010, Bob Loveless was an American cutler, whose palmares counts many high-facts. The legend tells that, then minor, he had changed his birth certificate to reach the merchant navy. His many trips led him to bars from all over the world, more or less famous, in which he would have attended many fights with the white weapon - of these shots would come to him his interest in the cutlery, in all his forms. Manufacturer "Delaware Maid" knives for Abercrombie & Fitch, staying for a long time among the best sales of the brand, co-founder of the Knifemakers' Guild (The Cutlery Guild) alongside Blackie Collins and John Nelson Cooper, his thirst for innovation in forge and manufacturing pushes him in turn, to introduce the use of the micarta for the making of handles knives but also to popularize the blades drop point Creuse and full silk knives. The story will also hold it back for introducing, and popularized, the use of steel that interests us today in cutlery.

From America to Sweden, a common goal: excellence

The story of Damasteel, like Robert Loveless's life, is a perpetual quest for excellence. The cutlers and blacksmiths around the world today know the reputation, and the legendary forge talents of the Swedish manufacturer. The promise of an easy-to-use inxogible steel, and cumulating the qualities, logically ends up interesting shovel Billgren, the founder of the company. Thanks to Bob Loveless, Damasteel MITS all his know-how for the development of a new steel shade, an improved version of the ATS34. To pay tribute to the American visionary, this new nuance was named RWL34 ™, taking up the initials of the one who introduced this nuance to the cutlers around the world.

Improved? Indeed, the company Damasteel was the first to produce the ATS34 by powder metallurgy, a method guaranteeing the quality and purity of the off-standards steel. A complex process we detailed in Our blog article about it. Results from this long and beautiful story a shade of exceptional stainless steel, all indicated for demanding cutlers.

RWL34™, a martensitic steel without shares

The RWL34 ™ is a condensed know-how, and conjugated talents of two countries. At the basic "recipe", developed by the Japanese and recovered by Bob Loveless, Damasteel Adds the process of the metallurgy of the powders of vanadium, which still increases the qualities of the ATS34:

- His design guarantees him a strongness, a hardness after quench and a purity at all events;

- It resists particularly well with corrosion;

- the cutting edge is maintained in time, and the cutting quality does not weaken;

- It's easy to work, grinding and polishing.

Its properties make it eligible for the followers of the mirror polite followers. For tips on RWL34 ™-adapted polishing pastes, and how to use them for optimal rendering, do not hesitate to contact SPAP SoucilleSpecialists from abrasive and polishing since 1962.

How to work the RWL34™?

Anxious to live up to the history of this steel, EuRotechni provides you with the technical sheet of the RWL34 ™, which you can find On its product sheet. In the latter, you will find valuable tips on how to work the RWL34 ™, but all the data needed to carry out its income and heat treatment.

If you are not equipped to do this correctly, EuRotechni can take charge of the heat treatment of your blades in RWL34 ™. You can find all the rates and our different services in our documentation, accessible by clicking here. And if you had the slightest question, our team remains at your disposal, by email or by phone.

Convinced by the RWL34™ ? Why not try it!

Trusted partner of Damasteel For many years, elected distributor of the year in 2017 and 2018, Eurotechni offers, for sale, steel bars RWL34 ™, in many dimensions, to suit all your needs: no less than 6 different thicknesses are available immediately in stock, Cut out of a meter or half meter bars, in various widths, depending on the type of blade you want to forge. We also offer this shade in the form of sheets, for the most ambitious projects (contact us for any request).

Find all our RWL34 ™ steel bars from Damasteel on our website, and Order them now!

For the pleasure of the eyes ...

Here are some knives, made by our customers, from RWL34 ™ steel. A big thank you to them for their photographs!