What is wood stabilization ?

Stabilization consists in impregnating a piece of wood with a resin or a polymer to improve its density, its durability its resistance to moisture and cracks. This process is particularly useful for softwoods or woods with fairs, such as cracks. Stabilized wood will also keep its hues lasting over time.

The interest of cutlery stabilization.

Wood stabilization is an essential technique for strengthening and preserving wooden parts, especially those used in the manufacture of handles knives. The NovaCure resin is a leading product to stabilize wood, ensuring increased durability and resistance, and for cause! It was designed by Novawood, German specialist for exotic and precious wood stabilization, who has been using it for years - that we are very proud to count among our suppliers. The stabilization of wood is a process that can be delicate: we wrote this guide to guide you, step by step, in the stabilization of your first blocks and platelets of wood !

Why use the NovaCure resin ?

The NovaCure resin is probably the best stabilization resin currently on the market. Easy to use (you can find its instructions on its technical sheet), it gives excellent results on dry woods, whether common or exotic. Nevertheless, in order to obtain optimal results, it is necessary to correctly prepare its stabilization session !

Prepare your stabilization of wood ...

Before starting the stabilization process, it is crucial to prepare the wood and bring together all the necessary tools and equipment.

Wood selection

Choose wood parts that lend themselves well to the stabilization process. Avoid tropical timber and some hardwoods like oak and buginga, which do not take stabilization well. In general, the densest woods take little, or not at all, the stabilization - this is for example the case of Arizona ironwood, extremely dense in the natural state, which will not absorb the resin at all.

Drying

Make sure the wood is as dry as possible to allow optimal resin impregnation. A wet wood will greatly compromise the stabilization.

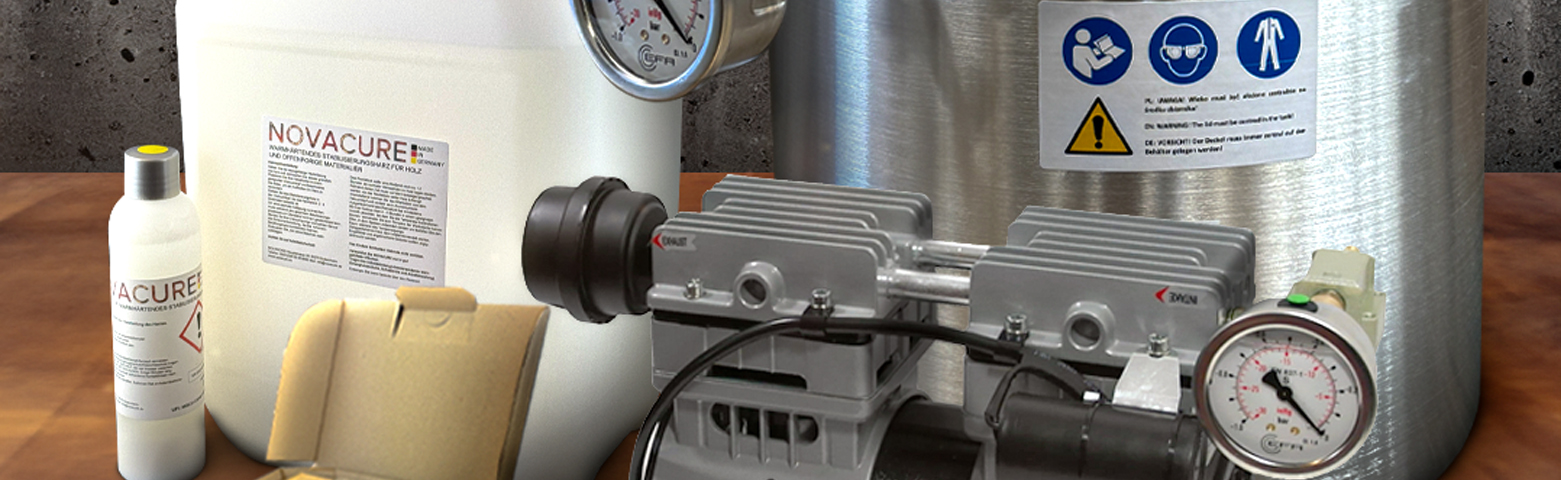

The necessary tools and equipment

- NOVED STABILIZATION RESIN

- Novavoid room and vacuum pump

- Adapted oven (laboratory furnace, for example)

- Nitrile gloves

- Protective glasses

- Aluminum foil

- And elbow oil !

How to stabilize your wood easily with novoceure ?

Activation of the resin

Resin preparation: Turn firmly the small activator bottle and empty its contents in the resin can.

Blend: Shake the can for a few minutes to mix the resin and activator.

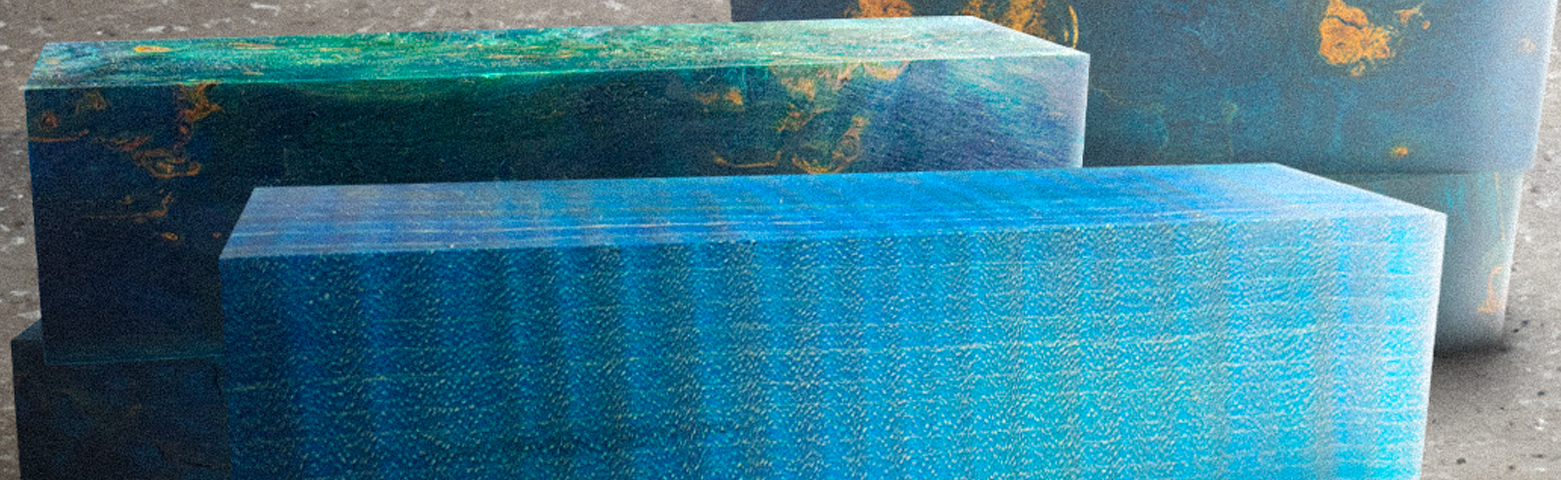

Dye : If you want to stabilize color blocks, pour the dye into the can (the amount will depend on the intensity of the desired color), and quite a firmly tight the set for several minutes.

Wood stabilization

Placement in the vacuum chamber: Place the wooden block to stabilize in the vacuum chamber. To avoid long and complex cleaning, we advise you to place the blocks in a flat container, itself placed in the vacuum chamber.

Adding resin: Pour the NovaCure resin on the block until it is completely covered (from 2 to 4 centimeters above the block). Drywood floates in most cases: for optimum impregnation, you can keep it at the bottom of the container with a weight. Rest assured, this will not prevent the resin from taking in the heart of the block !

Air Evacuation: Close the room and start the vacuum pump. Making a vacuum will unmatch the resin: you can eliminate the formation of this foam by regulating the pressure inside the room with the valve.

Regulate the pressure inside the chamber until the resin no longer runs, for optimal results.

Stabilization: Leave the block in the resin for about 12 hours, ensuring that the resin level remains above the block.

Tip: After having made the block for vacuum for 12 hours, open the chamber and leave the blocks are still gorging resin for 12 overtime, without pressure.

Hardening the resin

The hardener mixed with the NovaCure stabilization resin activates with heat: after stabilization, comes from the time of cooking !

Protection of the block: Take out the block of the vacuum chamber and wrap it into aluminum paper.

Cooking: Place the block wrapped in an oven adapted to at least 95 ° C for 4 to 5 hours.

Storage of the remaining resin: Resin remains can be reused if stored in a hermetic and clean container (the original can, for example), itself stored at room temperature, protected from light.

And that's all !

A problem? Solutions !

My stabilization resin makes bubbles is normal ?

Yes, it's the pressure that foams the resin. You can eliminate it easily by regulating the pressure inside the vacuum chamber.

I have the impression that my wood has not absorbed the resin correctly ..

Make sure the wood is completely dry before starting the process. Similarly, some particularly dense species do not take little, or not at all, stabilization - you will find a list in the NovaCure Resin.

The resin does not harden at the oven heater !

Check the oven temperature and make sure it remains constant at least 95 ° C for the required time (4 to 5 hours). Also check the folding of your papillote.

Wood stabilization: our FAQ

How can we know if the wood is dry enough for stabilization ?

The wood must be dried at a moisture content of less than 10%. Use a hygrometer to check the moisture content.

Can I use the NovaCure Resin on all types of wood ?

No, some woods like fresh oak, Bubinga and some tropical hardwoods do not take stabilization well.

How long should the wood stay in the resin ?

The wood must remain in the resin for about 12 hours for optimal impregnation.

What to do resin residues ?

Resin residues can be reused if they are stored properly in a hermetic and clean container.

What kind of oven should I use for hardening ?

Use a suitable oven that can maintain a constant temperature of at least 95 ° C for many. A housekeeper will do the trick, even if the precision remains a formidable allied !

Is it possible to color the wood with the NovaCure resin ?

Yes, you can add dye At the resin before starting the stabilization process to dye the wood. You can also make your own mixtures of dye to get unique hues !

How to maintain a handle stabilized wood ?

Stabilized wood requires little maintenance but must be protected from excessive shocks and prolonged exposure to water. It is still possible to avoid the shine with a cotton rubbing or a maintenance wax, like Wicked Wax wax.

In conclusion ...

Wood stabilization with the NovaCure resin is an effective method for strengthening and preserving your wooden parts. Following the steps and precautions described, you can get professional and durable results. Do not forget to always work in a well-ventilated environment and wear protective equipment.

Find all the stabilization stabilization stages in our video tuto, visible on YouTube !

https://youtu.be/4iohygr8bei